1957

1960

1964

1966

1968

1969

1970

1971

1973

1975

1979

1980

1980

1981

1985

1986

1990

1994

1995

1996

1997

1998

1999

2000

2002

2003

2007

2009

2009

2010

2011

2012

2013

2013

2014

2015

2016

2016

2016

2016

2018

2018

2023

.jpg)

.jpg)

.jpg)

Josep Mas founded the company Inyecciones Termoplásticas Mas. The company has 2 machines for transforming plastics into containers and packaging for the pharmaceutical industry, located in Cardedeu.

On March 12, the license for the exploitation of the Netlon patent and trademark was obtained. The company embarks on a new direction. One of the keys to achieving success was the personal friendship between Brian Mercer, the inventor of Netlon, and Josep Mas. In January 1960, the first contacts were established to found a company that would exploit the Netlon patent in Spain.

The company was renamed Intermas S.A. From there, throughout the 1960s, the company experienced growth: new products were developed for application in various fields, production facilities and offices were expanded, and the nets used in the manufacture of bags for packaging oranges appeared: rhombic and square meshes, and pallet covers. Intermas grew physically and productively in an unstoppable manner.

The license for the exploitation of the BERATEX patent for the production line of raffia for the agricultural sector was obtained.

Invention of the packaging COVER mesh by Intermas.

Intermas invents the 'R' Bag (3-thread mesh with a raffia loop) for orange packaging, achieving a strong impact on the market.

In 1970, the Cardedeu facilities included 6,502 square meters of industrial buildings and 570 square meters of office space.

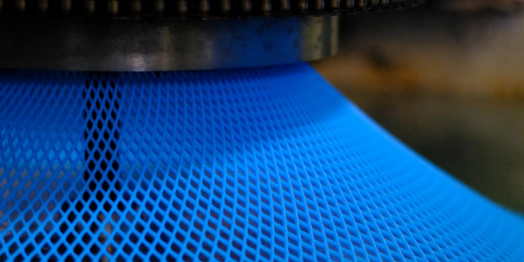

In the CollSabadell industrial estate in Llinars del Vallès, 20,750 square meters of land were acquired for optimal planning of the company's development and growth. That same year, the Quality Control department was established, essential given the rigor with which Intermas operates. Additionally, the proprietary design of the BOP mesh machine was developed for various industrial and agricultural applications, among others.

Intermas absorbed two companies located in the Collsabadell industrial estate, where its facilities are today; NOPLEX, a company that produced BOP nets, raffia, 'R' bags, and RASCHEL® sacks, and IGEMSA, a company that built machines for Intermas.

The Intermas network grows exponentially. From 1975, after analyzing current and potential market needs, Intermas has worked to introduce new products: POCHES, for the oyster farming sector.

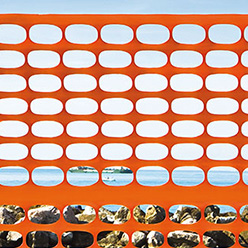

MASNET mesh for works signalling.

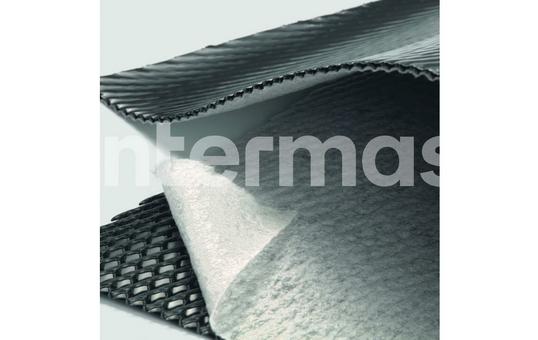

In the 1980s, drainage piping was manufactured. Its purpose is to capture water from the surface and within the soil, ensuring that the surface remains dry by evacuating absorbed water. Drainage mesh began to be manufactured in Cardedeu. In the 1990s, drainage mesh 2 meters wide was produced (for landfills, roads, etc.).

From the 1980s onwards, Intermas has continued to commit to a policy of reinvention and modernity, consistently advocating for the use of the most advanced technology, the most stringent quality controls, and ongoing customer service.

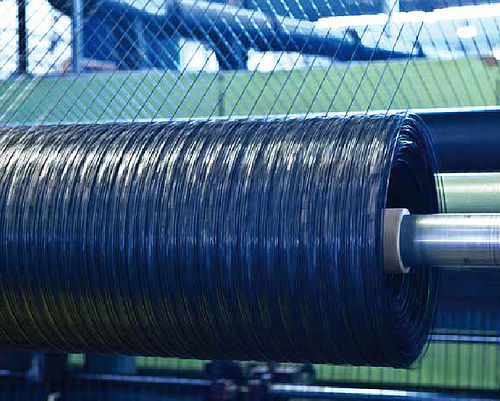

In 1981, the business expanded with an investment in production facilities to manufacture RASCHEL® woven mesh, which ceased production in 2003.

A principios de 1985 Intermas se ha By early 1985, Intermas had already become one of the leading industries in the plastic processing sector, not just nationally but also internationally. It exports to over 15 countries, employs a staff of 225, and has a significant commercial network with representatives across the entire national territory and in several foreign countries. Additionally, the facilities continue to grow: they now encompass 16,525 square meters of industrial buildings and 1,505 square meters of commercial and administrative offices.

The Linpac Plastic Group acquires Intermas S.A. and turns it into a subsidiary of a British multinational.

From the 1990s onwards, Intermas has been expanding its network of quality and productivity.

In 1994, we implemented the ISO 9001 quality standard.

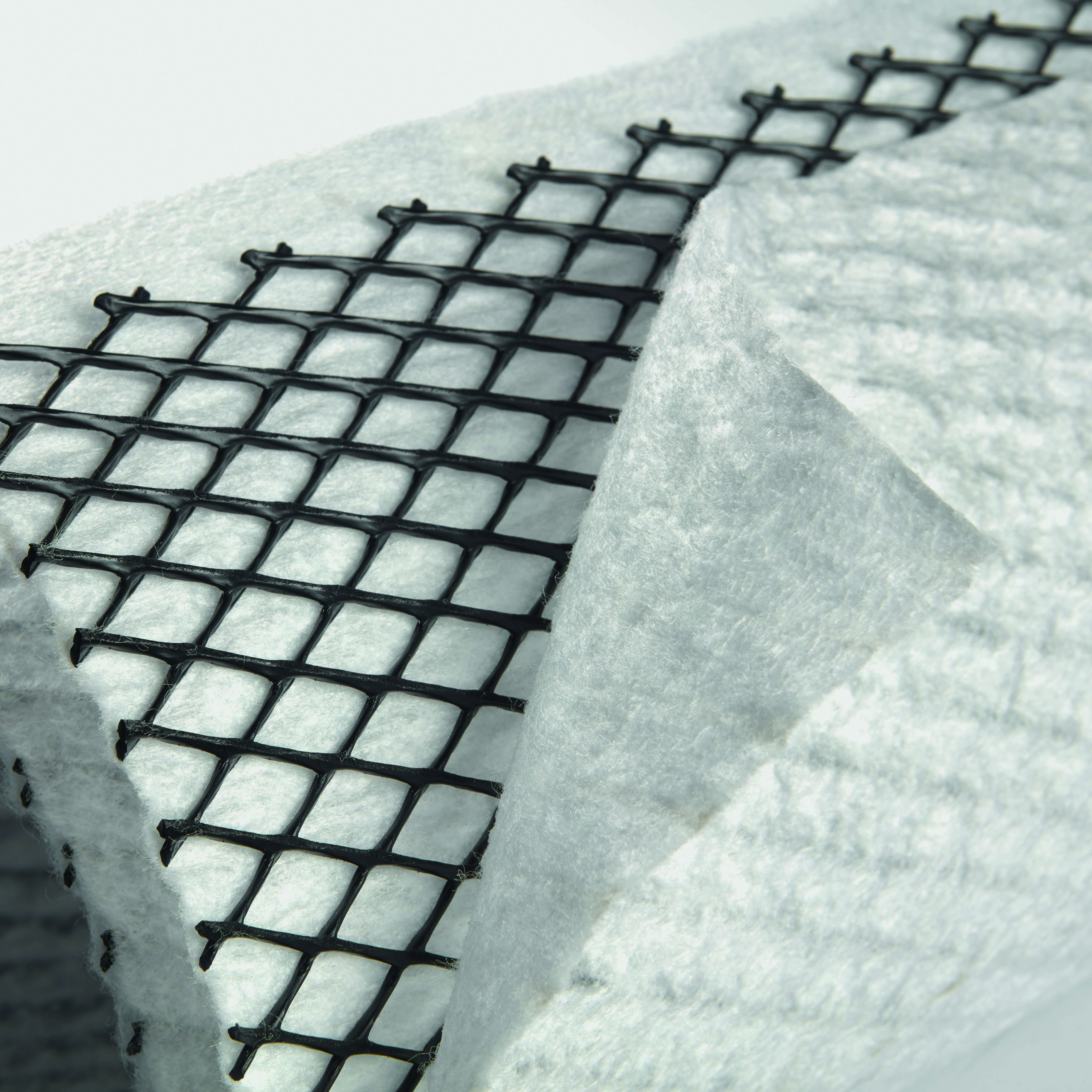

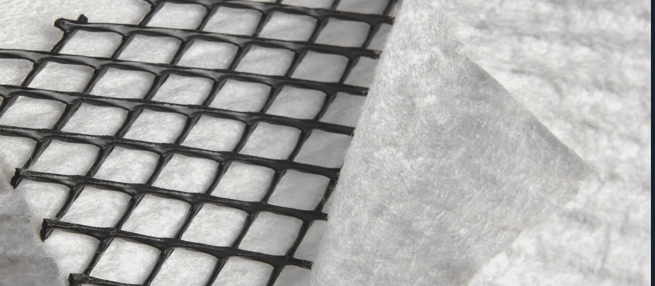

In 1995, we developed the lamination of meshes and geotextiles with a 4-meter-wide machine.

In 1996, a Management Buyout was conducted by Mr. Fort, Mr. Besas, Mr. Clavell, and Mr. Banus, along with 3I (Venture Capital Firm), leading to the creation of Intermas Nets S.L. This marked the beginning of the development of the first drainage products.

In 1997, a range of meshes for supporting and folding air filtration systems was innovated and developed.

In 1998, we obtained ISO 14001 certification: this is no small feat, as we are the first company in the plastic processing sector in Spain to achieve this.

At the end of the decade, in 1999, the company underwent a commercial reorganization into seven activities classified into three distinct divisions (gardening, performance & product development, and packaging). With this new structure, Intermas Nets strengthened its international presence with a plant in Mexico, which positioned the company in that country with quality, service, and price. Intermas Mexico was established in Tijuana.

Intermas continues with its expansionist purpose and establishes Intermas USA Inc. in California. The new millennium begins with significant news: the acquisition of Celloplast, located in Ballée (France

Exit of 3I in favor of the families from the Management Buyout.

In 2003, the Intermas Mexico subsidiary closed, but it is important to note the significant addition of Noplex Artes Gráficas S.L. to the company.

Banco Sabadell / Aurica XXI acquires 20% of Intermas Nets.

In 2009, as the company grew, so did its commitment to the environment: we began recycling oyster poches and transforming them into new products. The eco-friendly poches are made with 50% recycled material from other poches and the remaining 50% from virgin material.

Intermas Nets establishes a merger by absorption of Seilfil Percan and Magrotex and expands into new markets with Intermas Polska in Eastern Europe and Poland.

Intermas continues to focus on creativity, innovation, and new technologies. In 2010, we launched the Nortene® brand in Spain in the field of gardening and acquired Viscoret (Italy).

We inaugurated a new logistics center at Celloplast, which spans 12,500 square meters, and implemented SAP at Intermas Nets.

We implemented SAP at Nortene Technologies, which inaugurated its new factory in Lomme (France). The commercial headquarters of Jardins de Nortene was also relocated to Ballée, the headquarters of Celloplast.

In 2013, a team effort was initiated to define the common vision and mission of the Intermas Group, which included the ELAN 2016 project. Strong values that represent the Group and its employees were identified, with the goal of uniting teams and creating a strong company culture. In 2017, the Values Campaign was launched.

In 2013, we continued with the implementation of SAP, this time at Viscoret. Additionally, it was a significant year as we established the subsidiary Intermas Nets USA Inc. in Miami (USA) and dissolved the 'dormant' company since 2004, Intermas USA. A merger absorption between Celloplast and Jardins de Nortene was also completed, and the company was reorganized into two major divisions: BtoB and BtoC..

In recent years, SAP has been implemented at Noplex (2014), Celloplast (2015), Intermas Eastern Europe (2016), and at Intermas Polska and Intermas Nets USA (2017)

In 2015, we developed a new easy open and close system for poches (Open Bag) in the field of Aquaculture. We produce the ROCKSHIELD® mesh, a special mesh designed to disperse the impact of rocks on pipelines and oil pipelines, thereby reducing the damage caused by their concentration at a single point. In the field of Building, we launched the GA® underground signaling mesh, equipped with Eliot technology (a system for locating and identifying underground utilities using radio frequency)

At the beginning of 2013, it was decided to map out the organization in a way that outlined the steps to achieve our vision, turning projects into actions. The goal was to create guidelines that would ensure business volume growth and margin in the medium and long term for the Group. To achieve results, the Group was reorganized into two major divisions (BtoB and BtoC). It all started with studies of the different activities in each subsidiary. Division Directors, along with Activity Managers and teams, defined the strategy. This was an in-depth, detailed effort that had never been undertaken before. The collective teamwork was what led to the definition of a clear and explicit strategy for the group, a three-year business plan that was ambitious yet realistic.

In 2016, Intermas launched the MAS 3.0 Digital Transformation project to tackle the challenges of the Industrial Revolution 4.0. The Intermas Group defined its vision and digital strategy by focusing on projects that would turn it into a sustainable business model and create value, both for the company and its strategic partners. More than fifty staff members participated in five cross-functional working groups: 'Go to Market,' 'Operational Efficiency,' 'People and Performance,' 'IT and Data,' and 'The Lab.'Additionally, the Intermas Group actively works to develop digital skills and foster a digital culture within the company.

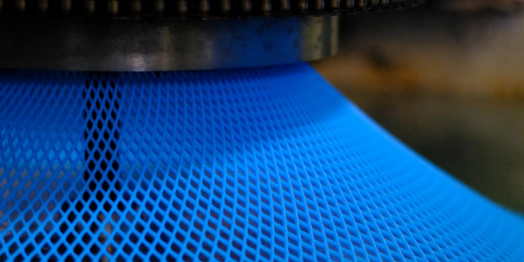

An investment was made in a new RAME machine, enabling the production of wide-width BOP meshes, primarily for the Agriculture sector.Within the Geosynthetics activity, a new three-thread drainage product (Capdrain®) was developed for landfill applications with high transmissivity.

Aurica XXI sells its 20% stake.Intermas Netherlands B.V. is established to strengthen the positioning of the Nortene® brand in the gardening sector.

Intermas® The production rollers inspire a new symbolism that allows us to play with shapes, giving rhythm and meaning to the brand.

Viscoret rebranded as Intermas Italy.

Intermas new brand

.jpg?width=915&height=405&name=IGS%20corporate%20member%20(sin%20el%20a%C3%B1o).jpg)

.jpg)

.jpg)