- The company

- Our Essence

OUR ESSENCE

Purpose, People & Planet at the Core

Driven by values, powered by people, committed to the planet.

For over 60 years, at INTERMAS we have been delivering innovative mesh solutions with a strong sense of purpose. We empower our partners and customers while protecting the planet in the most efficient and sustainable way.

Our mission is to create net solutions that contribute to a greener future—protecting water resources, food and vegetation, reducing environmental footprint, and enhancing safety and well-being.

We are guided by six core values: Audacity, Improvement, Effectiveness, People First and Trust. These principles drive us to challenge conventions, exceed expectations, and deliver solutions tailored to the most specialized needs.

As the European gold standard in advanced material net solutions, we combine technical expertise with a global vision—leading the way in innovation and quality to serve industries around the world.

At INTERMAS, we innovate with soul and responsibility—because our greatest asset has always been, and will always be, human talent.

Our contribution to society and the environment:

-

Protect water resources

-

Preserve food and vegetation

-

Reduce environmental footprint

-

Enhance safety and well-being

Mission

We create mesh solutions to empower our partners and customers while preserving our planet in the most efficient way.

We create mesh solutions to empower our partners and customers while preserving our planet in the most efficient way.

Vision

Europe's gold standard for advanced material net solutions, with global reach.

Leading the way in specialized applications for a greener tomorrow.

Europe's gold standard for advanced material net solutions, with global reach.

Leading the way in specialized applications for a greener tomorrow.

Values

AUDACITY

Our spirit of audacy encourages pioneering ideas & courageous until the extraordinary.

IMPROVEMENT

Driving perpetual progress and raising standards.

EFFECTIVENESS

Fostering effectiveness through agile leadership, ownership and tenacious problem-solving.

PEOPLE FIRST

Building a high-performing workplace through personal growth & engagement.

TRUST

Empowering confidence and fostering lasting relationships in everything we do.

AUDACITY

Our spirit of audacy encourages pioneering ideas & courageous until the extraordinary.

IMPROVEMENT

Driving perpetual progress and raising standards.

EFFECTIVENESS

Fostering effectiveness through agile leadership, ownership and tenacious problem-solving.

PEOPLE FIRST

Building a high-performing workplace through personal growth & engagement.

TRUST

Empowering confidence and fostering lasting relationships in everything we do.

Our Global Presence

Headquarters & Plant:

Intermas Nets SAU (Barcelona, Spain)

Plant & Offices:

Intermas France SAS

(Lomme, France)

Warehouse & Converting Plant:

Intermas France SAS

(Ballée, France)

Plant & Offices:

Intermas Italia srl

(Lomagna, Italy)

Offices:

Intermas Net USA Inc

(Miami, FL, USA)

Warehouse:

Intermas Net USA Inc

(Spartanburg, SC, USA)

Technology is in our DNA.

Netting Your Future

At Intermas, innovation drives us to always stay one step ahead. For over six decades, we have developed advanced solutions with cutting-edge technology to ensure the highest quality and efficiency.

Our mesh extrusion process transforms raw materials into structures tailored to the most demanding needs. Additionally, we apply our expertise to develop 100% recyclable and biocompostable materials, betting on a more sustainable future.

At Intermas, we don’t just create solutions, we create the future.

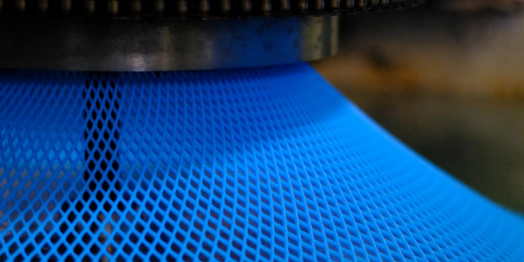

'Netlon systems' 'Reverse Rotation System

With this technology, two dies rotate in opposite directions. The dies have grooves through which the molten material flows. Due to their rotation, the mesh shape will always be diamond-shaped.

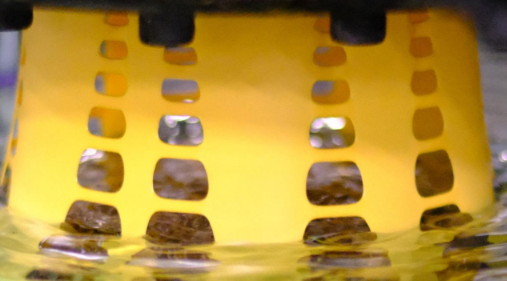

Trical 'Oscillation System

In the process known as Trical, only one die moves. The oscillation causes the material to flow and forms rings that solidify with the crossed filaments. The final product is a mesh that has angles of about 90º. Once produced, the mesh can go through other manufacturing stages that can considerably change the characteristics of the basic product: orientation, bi-orientation, or lamination.

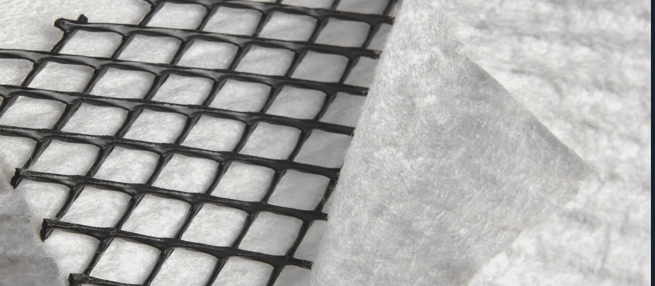

Lamination

In some applications, the extruded mesh is used as a support for another material. This process is called lamination and involves bonding the mesh to one or more materials. This combination enhances its effectiveness.

To combine the materials, they must be heated to the desired temperature, and then pressure is applied to achieve the fusion of the liquid molecules.

Subsequent Orientation and Bi-orientation Processes

Orientation is the process by which polymer molecular chains are aligned in one direction. This method is used to manufacture products intended for specific applications.

The chains can be oriented by applying a controlled temperature to stretch them longitudinally in the case of mono-oriented meshes, and transversally for bi-oriented products (BOP).

The result significantly increases tensile strength and reduces the mesh weight by decreasing the thread diameter.

Other processes

In addition to the processes described above, Intermas performs various types of complementary finishes for a wide range of products, aimed at facilitating and enhancing functionality during application.

Some examples include: cross cuts, die-cutting, perforation, welding, incorporation of bands, stitching, etc.

All of these finishing processes greatly facilitate the application of our products."

Reverse Rotation System" of the Netlon Systems

The main characteristics that define the meshes are the structure (thread shape, joint, thickness, angle, and distance between threads), the materials (raw materials + additives + dyes), the width, and the color.